Manufacturing

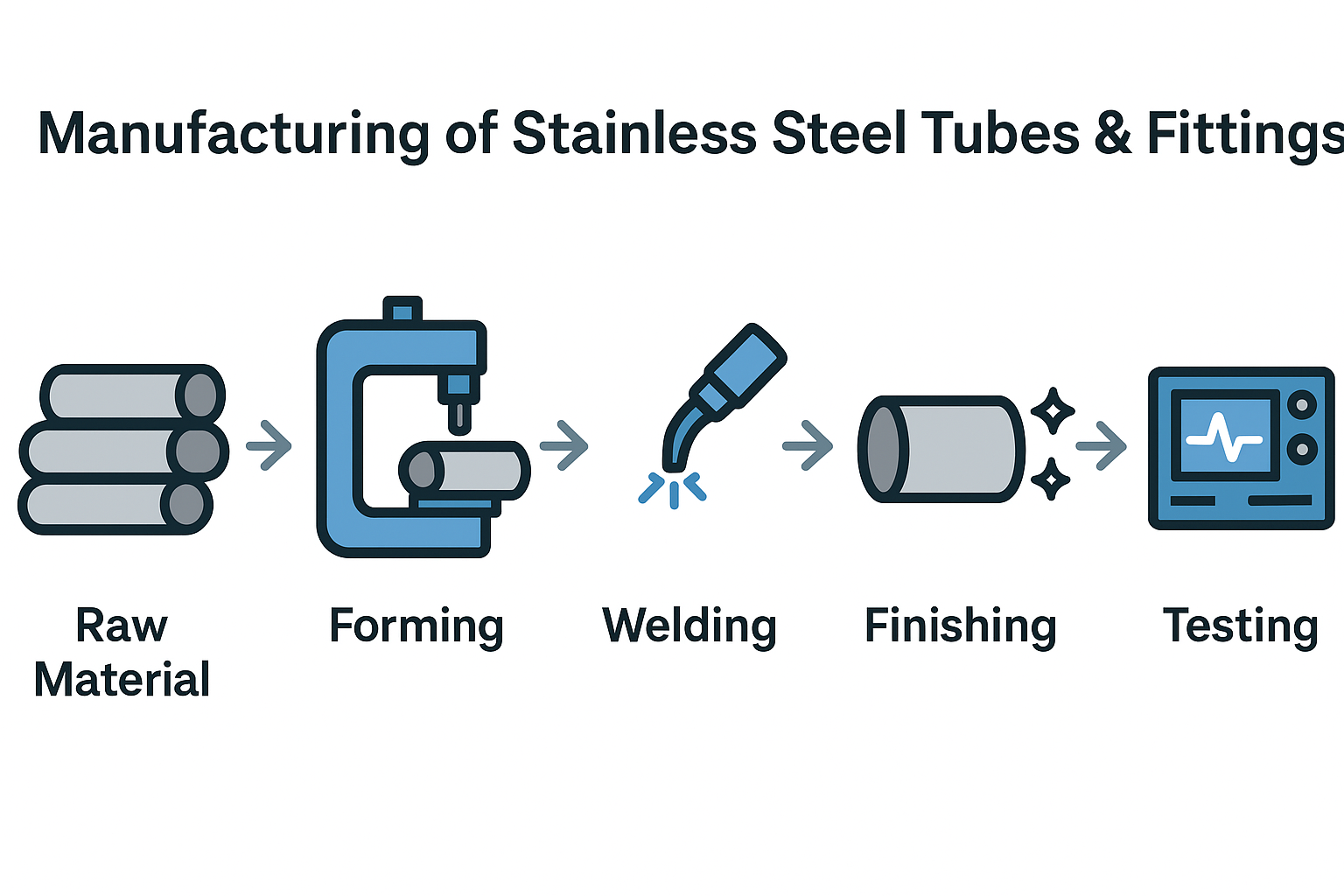

The Ratan Tubes & Engineering manufacturing facility is equipped with the latest technology, advanced machinery, and precision equipment. Our production capabilities include modern processes such as welding, machining, mandrel processing, and are supported by fully computerized systems for procurement, inventory management, production planning, and certification.

Key Manufacturing Processes:

- Advanced CNC-based angular cutting machines

- Non-melting electrode inert gas shielded welding (TIG welding)

- Fully automated orbital welding

- Mechanical polishing (up to SF1 ≤ 0.5 μm)

- Electrolytic polishing (up to SF4 ≤ 0.375 μm)

- CNC four-axis turning and milling machining

- Bright annealing furnace for superior metallurgical properties